CAD Designing Service

Home / CAD Designing Service

Affordable Jewelry CAD Design Services - Bring Your Jewelry Dreams to Life!

Are you dreaming of creating your own stunning jewelry pieces, but not sure where to start? Look no further! At Jewelry Rendering Service, we offer affordable Jewelry CAD Design Services that will turn your ideas into reality. Let’s dive into how our services work in simple terms.

Creating Jewelry with Technology

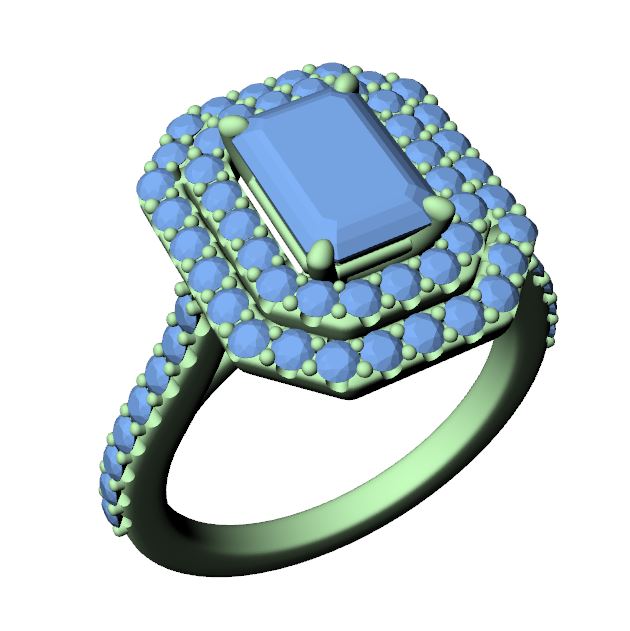

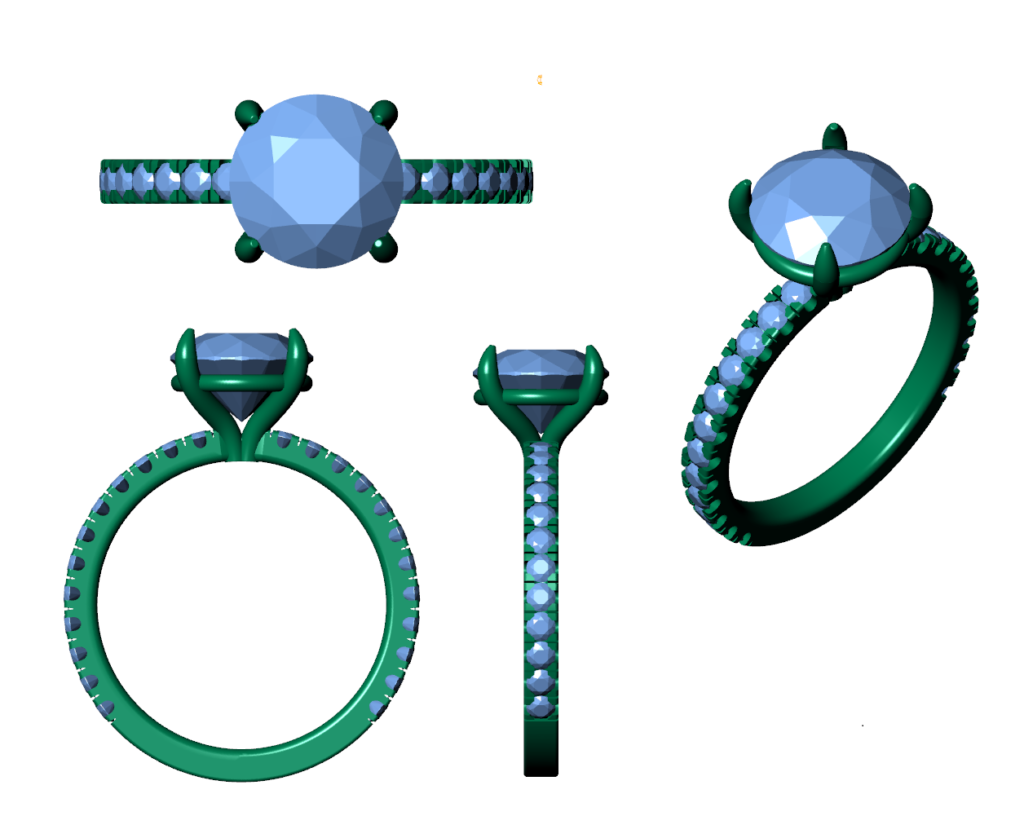

Imagine being able to design your dream jewelry piece with the help of a computer! Our talented 3D CAD designers can bring your jewelry ideas to life digitally. Whether it’s a dazzling diamond necklace, a beautiful gold ring, or a unique bracelet, we’ve got you covered.

All you need to get started is a sketch or a picture of your jewelry concept and the size dimensions you have in mind. Our designers will then transform your vision into a 3D design. This digital representation can be used to create a prototype, which is like a sample of your jewelry piece. You can use this prototype to show potential clients or manufacturers exactly what you have in mind.

Top-Notch Designers at Your Service

We take pride in our team of expert jewelry CAD designers in India. They are highly skilled and experienced, ensuring that your designs are in the best hands. We understand the importance of staying up-to-date with the latest techniques, and our designers are always on the cutting edge.

Fast and Efficient Service

In today’s fast-paced world of business, time is precious. That’s why we promise to deliver your final design images quickly, usually in just a few days. We believe in efficiency and want to help you keep up with the demands of your trade business. Plus, hiring our freelance CAD designer can save you money.

Enhancing Your Jewelry’s Value

Precise technical sketches are essential for creating intricate jewelry pieces. These sketches serve as the blueprint for crafting the real thing. Our Diamond and Gold Jewelry CAD Design Services ensure that every detail is captured accurately. We provide the language that manufacturers need to bring your vision to life.

Unlock the Power of CAD Modeling

In addition to our CAD design services, we offer a range of other services, including 3D product modeling and photo editing. We make it easy for you to find the right specialist for your project based on your unique needs. Creating a professional 3D jewelry design through our 3D product modeling services is the first step to turning your idea into reality. Our expert designers will make sure your project is a success.

Get in Touch Today

Ready to maximize the benefits of CAD design services? Whether you’re a large enterprise or a small business, we’re here to help. As India’s leading CAD Design Company, we cater to everyone.

What is the Difference Between CAD and CAM Jewelry Designing Services

CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) are two distinct but interrelated technologies that play crucial roles in the jewelry design and manufacturing industry. Understanding the difference between CAD and CAM jewelry design services is essential for anyone involved in this field.

CAD Jewelry Design Services:

CAD design services in jewelry involve the creation of digital 2D or 3D models of jewelry pieces using specialized software. This technology allows designers to meticulously craft intricate designs with precision and accuracy. The key aspect of CAD is its ability to create detailed and realistic virtual representations of jewelry items. Designers can manipulate these digital models, making modifications, and experimenting with various design elements such as gemstone placements, metal settings, and overall aesthetics. Keywords like “CAD jewelry design services” highlight the specific niche within the broader CAD domain.

CAD offers several advantages:

- Precision: CAD allows for precise measurements and exacting details in jewelry designs.

- Efficiency: Designers can create multiple iterations quickly, saving time and resources.

- Customization: Clients can request personalized jewelry pieces tailored to their preferences.

- Visualization: CAD enables clients to see a realistic preview of the final product.

CAD/CAM Jewelry Design Services:

CAD and CAM are often used together in the jewelry design process, creating a seamless workflow from design to production. After a jewelry piece is designed using CAD, CAM comes into play for manufacturing. CAM translates the digital design into tangible jewelry items by automating the production process. It controls machinery like CNC (Computer Numerical Control) mills and 3D printers to carve or construct the jewelry piece using the specified materials, such as precious metals or gemstones. By using keywords like “CAD/CAM jewelry design services,” you emphasize the integration of both technologies.

Here are some advantages of CAD/CAM jewelry design services:

- Consistency: CAM ensures that each piece is replicated accurately, maintaining design consistency.

- Speed: CAM automates production, allowing for faster jewelry creation.

- Complexity: CAM can handle intricate designs that may be challenging to craft manually.

- Material Efficiency: CAM optimizes material usage, reducing waste.

In summary, CAD focuses on the design aspect of jewelry, allowing for detailed and customizable creations. In contrast, CAD/CAM jewelry design services encompass both design and manufacturing, ensuring that the digital design is translated into a physical jewelry piece with precision and efficiency. These technologies have revolutionized the jewelry industry, offering designers and manufacturers powerful tools to create exquisite and high-quality jewelry items.

Frequently Asked Questions

First, a wax model of your design is created. This is then coated in a refractory material and heated until the wax melts and evaporates.

Once the metal has cooled and solidified, the mold is broken away to reveal your finished jewelry piece!

CAD design has revolutionized the jewelry casting process, making it possible to create highly detailed and complex designs that would be difficult or impossible to create using traditional methods.

Once the casting process is complete, your finished jewelry piece is ready to be polished and set with gemstones.

Traditional jewelry manufacturing often involves joining multiple pieces together, which can be time-consuming and lead to weaker joints. 3D printing offers a more seamless and efficient alternative, creating the finished design in one single piece for a stronger, more durable piece.

3D printing also allows for more complex and intricate designs, opening up new possibilities for creativity and expression.

Overall, 3D printing is a more efficient and creative way to produce high-quality, unique jewelry.